Product Description

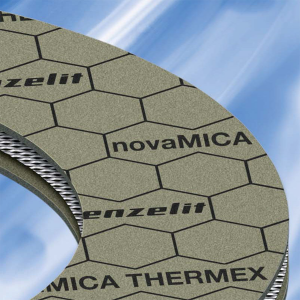

NOVAMICA THERMEX

Our materials made from optimised phlogopite mica have outstanding temperature resistance, chemical

resistance, electrical insulation and processing properties.

With the novamica® portfolio, we are supplying individual solutions for:

• Sealing at high temperatures up to 1000°C

• Sealing of aggressive / corrosive media at high temperatures

• Soft mica layers for metal gaskets

(e.g. grooved and spiral wound gaskets)

• Production of parts with filigree geometry

• Processability with all the standard methods (plotter, water jet, punch, shears, cutter)

Excellent material characteristics

The phlogopite mica used in the novamica® products resists temperatures of up to more than 1000°C.

Other mica materials are far less resistant. Muscovite mica starts to calcinate at about 600°C, for example,

while such structures as vermiculite that are similar to mica begin to calcinate at as low as 100°C.

With the material combination consisting of high-quality phlogopite mica, an efficient bonding system and

expanded metal (THERMEX), it is possible to produce premium solutions for a wide range of hightemperature applications.

The material combinations

| novamica® | THERMEX | 200 | 100 |

| High-quality phlogopite mica | | | |

| Stainless steel expanded metal insert | | ||

| High-temperature bonding system | | | |

| Product range | |||

| Sheets | | | |

| Reels | |

Technical details

| novamica® | THERMEX | 200 | 100 | |

| Density (* = modal value) | [g/cm3] | 1.80* | 1.80* | 1.60* |

| Thickness range | [mm] | 1.0 / 1.5 2.0 / 3.0 |

0.8 / 1.0 1.5 / 2.0 / 3.0 |

0.5 |

| Sheet length / width | [mm] | 1,200 / 1,000 | 1,200 / 1,000 | – |

| Reel width / length | [mm] | – | – | 1000 / 50000 |

| Material strength | | | | |

| Temperature resistance | | | | |

| Adaptability / flexibility | | | | |

| Sealing properties | | | | |

| Media resistance | | | | |

| Electrical insulation | | | |

Possible applications

Highly temperature-resistant

compensation element

Gasket with sophisticated

geometry

Electrical insulation Corrosive media

= Basically suitable

= Very suitable

= Highly suitable

Reviews

There are no reviews yet.